Roshiontextile is committed to cooperating with fabric factories to continuously develop and produce new sustainable fabrics, protecting the environment while improving the fabric functionality, Reducing the wastage and pollution to our earth,creating a green and health life!

1.Sustainable fiber:Currently We have more than 500 different various of sustainable woven fabrics,100 different knit fabrics. Which certificated by GOTS,GRS,LENZING ECO-Vero,EU flax certifiated linen

*fibers: organic cotton, organic linen, better cotton, bamboo ,aloe, corn, mint, Eco-Vero rayon,recycled cotton, recycled poly, recycled Tencel ,recycled nylon ,recycled leather.LENZING lyocell,LENZING rayon,EU flax linen.

*fabric types: Satin, chiffon, chino, taffeta, poplin, oxford cloth, jersey/rib in different weights, French terry in different weights, voile,tricot, tulle, mesh, flannel, Tencel, leather and pu. polar fleece, denim and canvas.

2.Sustainable way to produce fabric/garment: save energy ,save water when produce fabric, Do zero water wasted, zero harmful chemicals denim garment.

3.Functional fabric:such as Anti-bacteria, anti-virus fabric

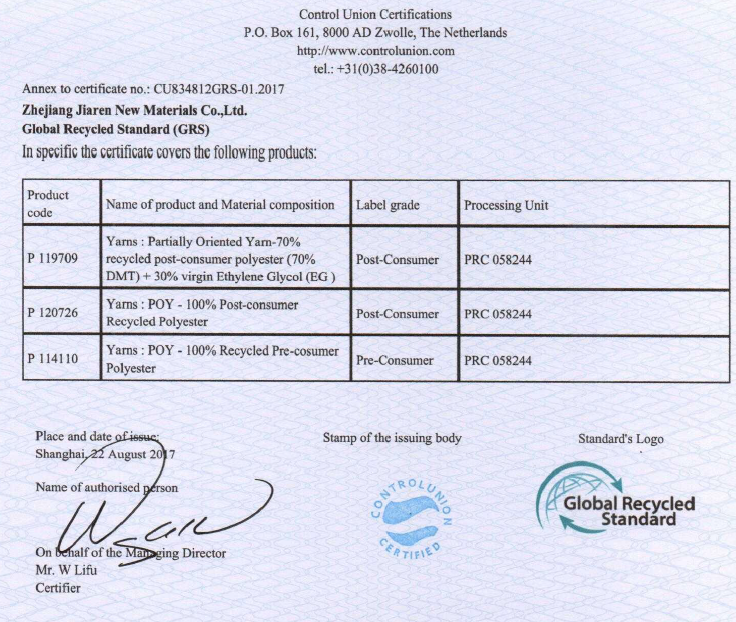

4.Sustainable certificated for garment:We have GRS/EU flax linen certificated for the garment finished product

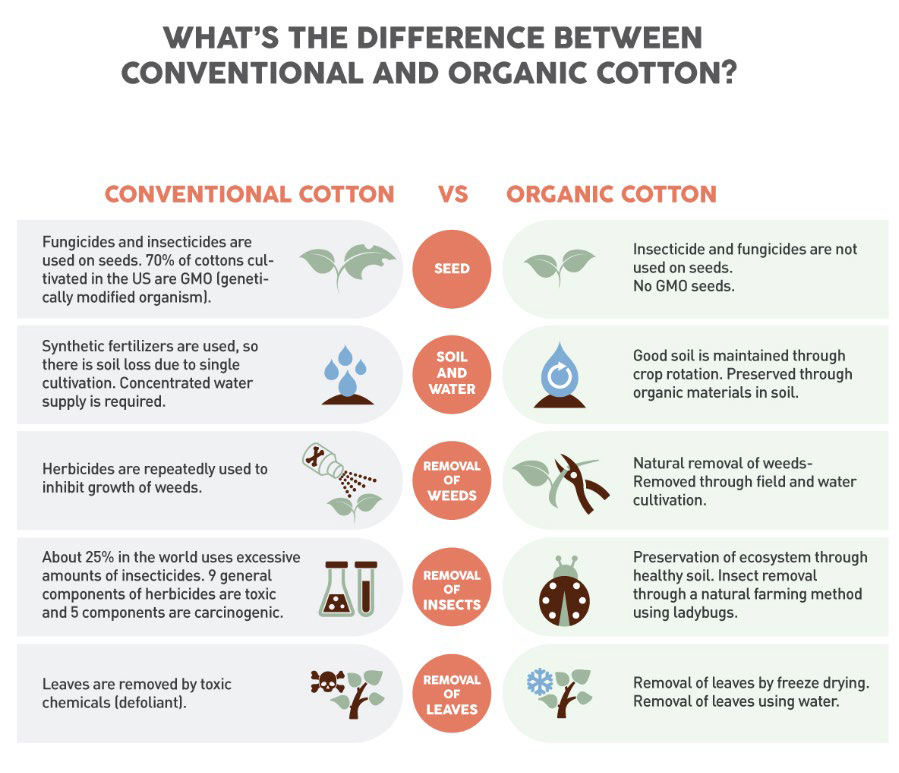

Organic cotton

Organic cotton is to use non-transgenicseeds to grown in an environment where no pesticides, chemical fertilizers, or herbicides have been used for a minimum of three years.

Garments made of organic cotton use less water in the production phase than traditional cotton fabrics. At the same time, they are often softer and more comfortable for the wearer. With organic cotton, your body is not absorbing all the nasty chemicals.

Recycled polyester--Fabric from Plastic Bottles

Recycled Polyester (RPET)has been developed using the clear plastic water bottles, or PET as the raw material. PET is the name of the resin used to make light, transparent bottles for drinks, juices, soap and etc. PET is 100% recyclable.

HOW TO TURN A FEW PLASTIC BOTTLES INTO POLYESTER FABRIC?

1. The collected PET bottles are sorted at a recycling facility where are sterilized, thoroughly cleaned, dried andthe labels are removed.Then, the bottled are separated by color (For producing a white polyester yarn -clear bottles, for green polyesteryarn -green bottles).

2. The bottles go into a grinder where are ground into small chips.

3. The chips are heated and dried to remove any moisture.

4. The dry chips are shoved through hot pipesto melt them into a liquid. The liquid gets filtered through a dye plate with tiny holes.

5. The filaments are then harden and pool and are sent over air rollers.

6. The machine spools the yarn and stretches it.

7. This yarn is then dyed, made into bales and ready to be woven into polyester fabric.

The recycled PET yarn can be used either alone or together with other fibers to weave a fabric. These fabrics were used to create strong, durable items, such as coats, shoes, bags, jackets, accessories.

Recycling Facts:10 plastic PET bottles = 1 lb(0.45 kg) of polyester fiber.Recycling PET bottles takes 8 times less energy than produce of new ones

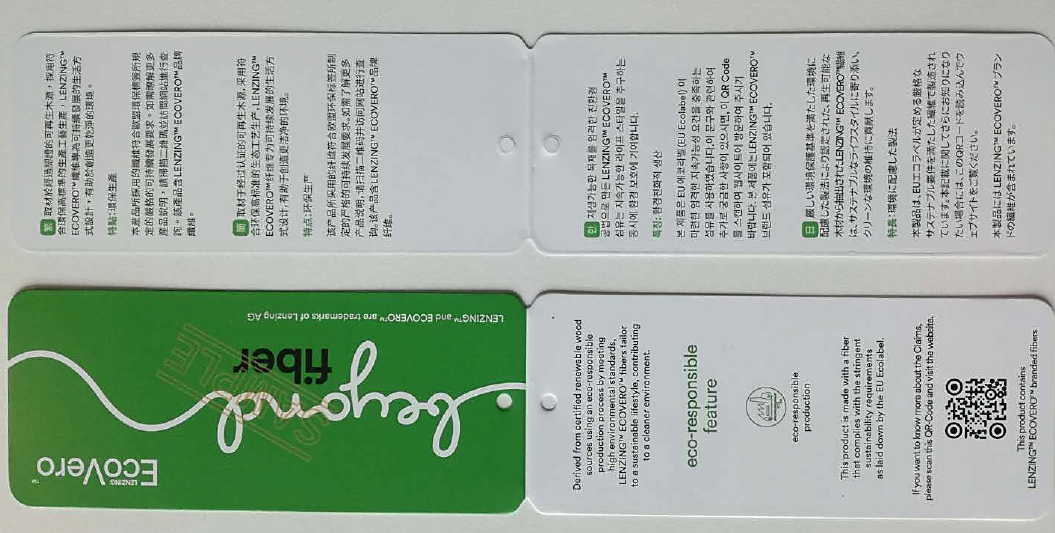

LENZING ECOVERO Viscose fibers

*up to 50% lower emissions & water impact than generic viscose

*sustainable wood and pulp sourcing/procurement

*supply chain transparency

*certified eco-responsibleLENZING ECOVERO Viscose fibers are derived from sustainable wood and pulp, coming from certified and controlled sources.

LENZING ECOVERO fibers have been certified with the EU Ecolabel as meeting high environmental standards throughout their life cycle: from raw material extraction to production, distribution and disposal.

EU flax certificated Linen

* Flax cultivation in Europe requires minimal irrigation and pesticides compared to other crops like cotton.

* The flax plant is a carbon sink, absorbing significant amounts of CO2.

* European flax linen production is often associated with ethical and sustainable practices.

* Linen is biodegradable and can be produced with low environmental impact, aligning with the growing demand for sustainable fashion.